Pump Repair and maintainaince by Pumpsets.

Pump repair and maintenance is a core part of our offering at Pumpsets as we have considerable experience across many industries. our objective is to ensure that you have the right pumping solution and that it provides you with as low as possible 'whole life operating costs'.

Pump repair and maintenance is a significant factor in the total ownership cost and keeping plant in good condition and optimised will save energy, prevent downtime due to breakdown and reduce the chance of a serious and potentially expensive failure.

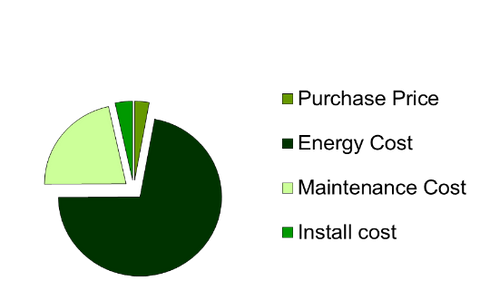

After energy costs, the cost of maintaining pumping plant is often the second highest expenditure of pump ownership, quickly exceeding the original purchase price of the pump. Regular maintenance and replacing of wearing parts keeps the pump running longer and saves on energy by making sure the pump performance is optimised.

Also in News

Yanmar L48V Diesel Engines with 5/8" threaded shaft for Sale

PumpSets have a number of Yanmar L48V recoil start diesel engines for sale, these engines have a 5/8" threaded shaft and are Stage V emissions compliant for UK installations.

Our price for supply of these engines is £1,554.00 Nett each ex works, ex vat

Please contact jon@pumpsets.com or ring 01264 332004 for full details

Lombardini 15LD225 Engine for sale

PumpSets have available a number of Lombardini 15LD225 (K No ED7A 0072) recoil start diesel engines for sale. These Engines have a 5/8" Threaded shaft and are not Stage V emissions compliant.

Price per engine is £1,356.00 Net ex works, inc vat

Please contact jon@pumpsets.com or ring 01264 332004 for full details